What is Cogeneration?

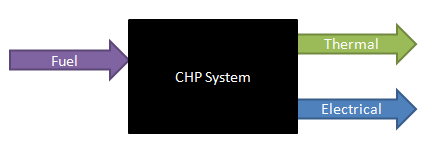

Cogeneration is when one fuel source satisfies two different power requirements. In the design presented in this website, natural gas will satisfy both heat and power requirements for an aquaponics system. This is known as combined heat and power (CHP). The generator will provide electrical power for water aeration, circulation, and artificial lighting. The thermal capacity of the CHP system will be used to maintain tank temperatures at approximately 80°F year round. The benefit of using cogeneration for this application, when properly sized for the thermal load, is an overall efficiency as high as 93% compared to an efficiency of 30%-35% for coal-fired power plants. This results in a reduction of greenhouse gas emissions along with lower operating expenses.

CHP systems are generally identified by the prime mover. In general, diesel and natural gas engines are common and economical. Diesel engines are known for high efficiencies and are capable of operating with a large range in fuel quality which can include bio-diesel or algae-based diesel. Diesel engines have relatively high emissions of NOX and particulates, while natural gas spark ignition engines have superior emission profiles [10]. Natural gas generators are the most common for CHP applications and routinely achieve overall efficiencies between 65-80% when combining electrical and thermal power output [10].

Aquaponics and CHP are a natural fit. Pumps and compressors must be run, and the tank must be heated. There are both thermal and electric load requirements which could be met with a CHP system. It is also be possible to use the waste stream of an aquaponics system to create biogas by anaerobic digestion to power a natural gas, reciprocating internal combustion engine for cogeneration.